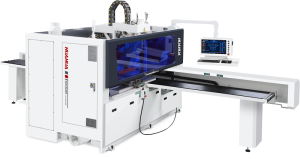

Ensuring Efficiency and Precision with HUAHUA’s Double-Sided Edge Banding Machine

In the world of furniture manufacturing, precision and efficiency are paramount. HUAHUA, a leading provider of woodworking machinery, understands this need and offers a cutting-edge solution with their CNC drilling machine-HH-2506R Double-Sided Edge Banding Machine. This innovative machine is designed to streamline the edge banding process, maximize productivity, and deliver impeccable results. Let’s delve into the features and benefits of this advanced solution.

- Double the Efficiency

With double-sided processing capabilities, the CNC drilling machine-HH-2506R doubles your productivity by simultaneously handling both sides of the panel. This innovative design reduces processing time, allowing you to complete more projects in less time. By optimizing the edge banding process, HUAHUA enables you to meet demanding production schedules without compromising on quality.

- Synchronous Conveying for Standardized Processing

The CNC drilling machine-HH-2506R features a synchronous conveying device, ensuring a standardized edge banding process. This means consistent and reliable results across all panels, eliminating variations caused by manual adjustments. The machine’s precision and reliability contribute to the overall quality of your finished products.

- Left and Right Conveying for Enhanced Flexibility

HUAHUA’s machine incorporates a left and right conveying device, enabling through-type processing. By eliminating the need to flip panels, this feature significantly shortens the panel distance during production. As a result, you can maximize the utilization of each edge banding machine and optimize your floor space.

- Intelligent Control and User-Friendly Interface

The HH-2506R is equipped with a 7-inch color control screen that provides a user-friendly interface for effortless operation. The touch screen display simplifies machine setup and adjustment, reducing the learning curve for operators. The concise and clear operation prompts ensure smooth and error-free production.

- Precision Trimming for Flawless Results

The machine’s end cutting unit, equipped with high-frequency motors, ensures precise trimming of protruding edge banding strips at both the front and rear ends of the panel. This trimming process guarantees a flush and smooth surface, enhancing the overall aesthetics of your furniture pieces.

Conclusion

HUAHUA’s HH-2506R Double-Sided Edge Banding Machine combines cutting-edge technology with user-friendly features to revolutionize the edge banding process. By increasing efficiency, ensuring precision, and offering versatile functionality, this machine empowers furniture manufacturers to elevate their production capabilities. With HUAHUA’s commitment to quality and innovation, investing in their edge banding machine is a step toward achieving superior results in the furniture manufacturing industry.